- Implementing CITES Regulations to Advance the Paphiopedilum Industry

- Safeguarding the Luffa Industry: A New Domestic Disease-Resistant Rootstock Option.

- Growing Bougainvillea by the Book – Your Guide to Becoming a Green Thumb

- Tomatoes on Eggplant Roots – The Secret to a Great Harvest

- The new favorite of therapeutic horticulture education --the application and promotion of succulent plants

- Welcoming Summer: Vigilance against Seedling Diseases in Cucurbit Crops – Integrated Management for Precision Control

- Vegetable Seedling Nursery Health Management: Promoting Industry Upgrading

- Germplasm Propagation and Renewal: Maintaining the Vitality of the Seed Noah's Ark

- Onion Seed Pelletizing Technology Improves Seedling Transplanting Efficiency and Reduces Labor Costs

- The Oncidium Healthy Seedling Propagation System 2.0 - Building a Sustainable Supply Chain for Healthy Cultivation of Varieties, Seedlings, and Cut Flowers

- Has the Dancing Lady (Oncidium) Had Its Health Check? Promoting Pathogen Testing for Oncidium Mother Plants

- Taiwan Seedling Improvement and Propagation Station collaborate with Xinshe oyster mushroom growers to complete product carbon footprint assessment

- Establishment of Organic Seed Production and Supplying System for Grain Crops-Soybean

- Major Advancements in Seed pelleting technology, More Labor-Saving in Seedling Cultivation and Planting

- Discover Heartwarming Green Therapy:The Adorable Succulents at Xinshe Flower Sea!

- One-Stop Solution for Growing Healthy Ginger: Select the Best Seedlings, Harvest the Best Ginger!

- Taiwan's Seed Industry Aligns with International Quality Control Standards Bio-Open Lab Now Open for Applications!

- Public-Private Partnership for Seed Sorghum Production

- Mass production and germplasm preservation of specific virus free Tainung No. 1 passion fruit through tissue culture

- Seed Conservation among Farmer:Cultivating Talent in Grains Germplasm Conservation

- Cucumber TSS No.3 Obtains Variety Rights, Appears Brilliantly, New Opportunities for Vegetable Industry

- Enhancing Oncidium Healthy Seedling Management for Superior Quality and Yield

- Mass production and germplasm preservation of specific pathogen free passion fruit through tissue culture Innovating to ensure healthy guaranteed seedlings for the industry

- Mushroom Production Integrates Recycling to Achieve Net-Zero Emissions

- Potato Industry Upgrade: Healthy Seed Potatoes as the Backbone

- Active Aging and Community Green Care Building a Successful Model

- High-Quality Cherry Tomato (TSS AsVeg No. 25) Grows in Popularit

- Vegetable germplasm of ark - germplasm conservation diversity and utilization of weather-resistant strains.

- A Wizardly Aid in Seed Quality Control and Plant Breeding

- The successful conservation of indigenous millet germplasm and keep the seed retention within the tribe

- The new silage corn variety "Tainong No. 8" was successfully produced and on sale

- International Level Seed Testing Laboratory Protects the Quality of Taiwan Seed Product

- Eat the Seedlings, Eat Healthy

- TSIPS has established cocoa pollination technology to increase yield

- Phalaenopsis Industry Informatization- Matching-Service Platform of Phalaenopsis’ Varieties and Industry is now available!

- The Guaranteed Quality of the MIT Seeds Helps the Seed Industry to Create Export Value ─ An Integrated Multi-Service Platform for Seed and Seedling Testing

- If farmers want a good taro harvest, they must have good taro seedlings Participatory high-quality seedling selection and cultivation management is close to the needs of farmers in the region

- The Air-Pruning root pot seedlings with First Class Qualities for Net Zero Emission and Greening

- TSIPS Expands the Domestic Grains Seed Production to Ensure the Food Security

- The key to providing A+ seedling products and services! Seamless transition to ISO quality management

- The healthy vegetable Okra ---looking for opportunities for global warming

- It is really convenient of ordering seedlings online, the Intelligent Vegetable Seedling Production and Sales Management System is connected with LINE@ Official Account

- Blueberry micropropagation technology enhances the market advantages of blueberry production

- The summer Chrysanthemum variety ‘Caroline’ is re-glory in Taiwan cut flower market.

- Artificial Intelligence Technology on “One-Second” Weed Seed Identification

- The first double-certified domestic organic seed production in Taiwan Seed Improvement and Propagation Station, COA

- Artificial propagated lady’s slipper for exports certified by TSIPS earned international recognition

- A good strategy to use by-products of vegetables and fruit as the feed additives of layer diets to improve egg quality

- A Bio-Open laboratory could be applied for use authorization and support R&D of the seed industry

- No worries for the seedling nursery, TSIPS can help ! “Vegetable Seedlings Intelligent Production Management System”

- The management of plant tissue culture has been further improved. The Taiwan Seed Improvement and Propagation Station(TSIPS) promote the advanced version of the plant tissue culture intelligent produc

- The Popular Bromeliads in the Crisp Autumn

- The International Connection of Seed Testing – Current Participation of Taiwan in International Seed Testing Association

- Midsummer Light Travel to Mountain City Walk Into the Forest and Embrace Nature to Relieve Stress--Anniversary Agricultural Leisure Tourism Marketing in Mountain City

- The "Wanshou fruit" variety has evolved again! Successful selection and breeding of new varieties of papaya with high yield and storage and transportation!

- Colors Dancing in Summer - Caladium New Variety ‘TSS No. 2- Red Heart Emerald’ Obtained Variety Rights

- Value-added processing on Taiwan fruits with a stunning new experience

- Green Healing Item--Development of Moss Tissue Culture Technology

- A Plant Species Named Toad but Not a Toad — a Casual Talk about Begonia

- Seriously? The first verified organic seed processing plant is at Xinshe, Taichung!

- Banana Seedlings Princess - Female Young Farmers Prop Up the Seedling Industry

- A new variety of potato ‘TSS No.6’ -Rich taste of the chips, fresh eating as well

- Tips for Growing Tiny Succulents on Your Table - Making You an Instant Green Thumb

- Taiwan Seed Improvement and Propagation Station is cooperating with Shinshu University to analyze the virus resistance mechanism of C. metuliferus

- Tomato Multiple pathogen detection chip development by TSIPS To reduce pathogens test time and cost

- The Romantic Seasonal Scenery of Golden Rain in Early Summer ─ Golden Shower Tree Flower Season talking about the mass production of golden shower tree seedlings

- Advance deployment by Taiwan Seed Improvement and Propagation Station for the Security Supply of Domestic Upland Crop Seed

- TSIP and agricultural leisure industry promote romantic journey of Twinkling Fireflies in The Tung Blossom Season

- TSIPS has established cocoa nursery technology to strengthen cocoa seedlings

- Gorgeous and bright colorful show~ competition of the first domestic sweet peppers in winter

- TSIPS’s testing service helps the last push to reach the goal of seed export

- Quality Assurance Sustems for TSIPS Plant Tissue Culture - ISO 9001:2015 Certification of Strawberry G0 and G1 Healthy Seedlings

- Seed testing laboratory passed the ISTA accreditation! More common crop and tree seeds can be tested now!

- 2019 Sea of flowers in Xinshe is coming

- Introduction of new field corn - Tainung No.7'

- Surprised! ‘Male infertility’ in plants is a good thing

- Green bamboo shoots are in season! Using healthy seedlings for farmers produce good bamboo shoots.

- The Last Piece of the Puzzle in Taiwan's Organic Industry —the Organic Seed (Seedling) Production System

- Seed becomes gold -Talking about the quality control of the green gold industry

- The new Facebook check-in place:Bai-Leng Irrigation Canal and Seedling Cultural Exhibition hall

- TSIPS established cocoa grafting technology to enhance farmer’s income

- DUS Testing of New Varieties of Phalaenopsis in Taiwan Has been Certified the International Standard for Service Management System

- The best helping hand for breeders- Biotechnology-assisted precision breeding collaboration model

- The Floating Fragrance Intoxicating to Bees and Butterflies in Summer-Mori Cleyera

- 1Domestic grain seeds with international quality certification

- Developing young home gardening customer source and establishing the foundation of food and agriculture education.

- Development of Papaya healthy seedlings that have been certified with ISO 9001

- Good taste and heath on bitter and sweet fruit vegetable in summer - bitter gourd

- New developed all-hermaphrodite molecular markers boost the papaya breeding efficiency

- It is a time to grow cowpeas and here is a new choice: Grafted cowpea seedlings for resistance to Fusarium wilt.

- The Peculiar Plant - Gac

- Artificial Intelligence Technology in Seed Packaging Work

- Connection between ICT Technology and Plant Seedling Industry – the Intelligent Vegetable Seedling Production and Sales Management System

- The Intelligent Image Recognition System for Assisting Paddy Seed Inspection

- New Hangju seedling propagation method!

- The Stunning Cherry Blossoms in May ─ Pink Shower Tree

- Protecting lady’s slipper in the orchid family

- Cherry tomato ‘TSS ASVEG No.22’- high quality hybrid seeds are now available for order

- Delicious, nutritious and healthy pumpkins

- Agricultural ISO testing laboratory for seed and seedling quality check

- Certified seed potato: healthy and high Yields

- The crop with bright white flowers- buckwheat

- The black rice rises – Specialized production area is the solution

- The 2016 watermelon contest will be held in Taiwan Seed Improvement and Propagation Station

- Multicolor fairies in summer- Caladium

- Best GM goalkeeper! TSIPS has established 21 detection methods for GM plants

- The King of Forages – Corn Silage Production

- Seed Testing Laboratory has moved to TSIPS!

- Hybrid Seed of High Quality Cherry Tomato ‘TSS ASVEG No.22’ is coming soon!

- Disco ver Beauty & Fragrance from Foxtail Orchid

- Sex type identification of papaya seedling by molecular markers

- The First ISO 9001 Certified Laboratory of Plant Tissue Culture in Taiwan

- The Master of Decoration ─ Bromeliads

- A good helper -rice seed image identification system to seed testing

- High Quality Cherry Tomato Hybrid Seeds of ‘Tainan ASVEG No.19’ and ‘TSS ASVEG No.22’ are available!

- Cross-Strait Plant Variety Protection Cooperation March Toward A New Milestone

- The purity testing system of watermelon seeds developed by TSIPS

- Well Control of Disease Makes No Worry While Strawberry Nursing Period

- The Master of Colorful Decoration ─ Cockscomb

- Give you a reliable and real-time information of seed industry - Asian Pacific Seed Industry Information Services Platform

- Molecular markers for pathogen resistance in tomato

- A N ew P roduction M odel of T raditional Chinese M edicin al H erbs- E stablish the S upply C hain in Taiwan

- Take care of pest control for planting green manure crops in fallow lands after second rice crop season

- The Blossom Paphiopedilum

Home > News > Mushroom Production Integrates Recycling to Achieve Net-Zero Emissions Home > News > Mushroom Production Integrates Recycling to Achieve Net-Zero Emissions |

Mushroom Production Integrates Recycling to Achieve Net-Zero Emissions

Xinshe District (Taichung) is the most important bag-cultured mushrooms production area for oyster and shiitake mushrooms due to its suitable climate and environment. The annual production is as high as 2,700 tons, accounting for more than half of the total output in Taiwan. Therefore, Xinshe is also known as the "Hometown of mushrooms." In the past, used bag-cultured materials were not properly recycled and disposed of, resulting in environmental problems such as littering, on-site burial, or burning. Today, used mushroom bag-cultured materials are recycled by licensed recycling facility to reuse the mushroom sawdust, which is rich in organic matter.

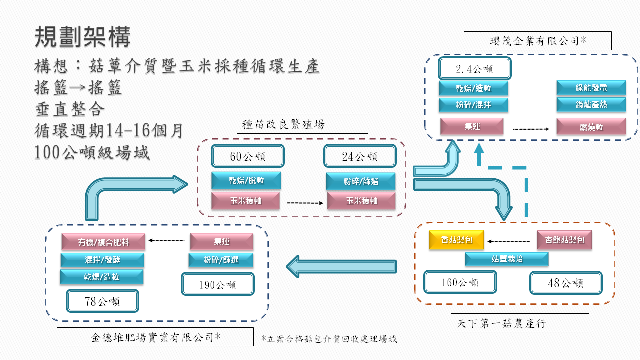

Taiwan Seed Improvement and Propagation Station (TSIPS) embraces the concept of co-prosperity with the local agricultural industry and the policy of agricultural net zero by 2040. It is committed to building a low-carbon and sustainable circular field. The TSIPS annually produces 40 hectares of corn seeds to meet domestic planting needs. In addition to certified seeds, 10-20% of corn cobs are also produced, which are good filling media for mushroom cultivation. This can reduce the number of trees that need to be cut down and imported materials for mushroom bags. In addition, the corn seed cultivation field has also been tested using a new compound fertilizer developed by a cooperative factory that blends mushroom bags and livestock manure. The preliminary test results showed that the yield is good, which can further expand the use of agricultural surplus resources. Finally, mushroom sawdust can be granulated alone or mixed with tree branches and corn dregs to press biomass fuel pellets. This type of biofuel emits carbon dioxide when burned, which is balanced with the carbon dioxide absorbed by plant growth. Therefore, it is considered to be zero-emission and is a green and clean renewable energy. The TSIPS has realized the sustainable agricultural circular production field of mushroom cultivation, used bag materials recycling, and crop production through the integration of three industries in Xinshe District, and reduced carbon dioxide emissions during the production process. In the first year of the trial, it is estimated that 2,560 tons of residual materials have been successfully recycled and more than 1 ton of carbon dioxide emissions have been reduced.

The carbon emissions of the agricultural sector in Taiwan account for less than 3%, but it is the best solution to reduce carbon emissions in line with the current emphasis on "nature-based solution". Through the adjustment of production methods with the integration of industries, it can effectively respond to the development and utilization of large-scale agricultural surplus resources such as used bag materials, fruit tree branches, livestock manure, and plant dregs in the region. In the future, it will continue to expand the scale of the trial and establish a commercial operating model to promote it to other mushroom production areas. Through scientific measurement methods, it is estimated that the environmental benefits of gradually reducing carbon dioxide emissions can be realized, and the participation of agricultural net zero emission reduction will be enhanced.

Fig. 1、Mushroom Substrate Cultivation and Corn Seed Recycling Production System

Fig. 2 Mushroom sawdust recycling and reprocessing organic compound fertilizer and corn dregs pressing biomass fuel pellets

| Contact Person | TSIPS Associate Researcher and Section Chief Chen,Jen-Ren |

TSIPS Senior Researcher and duty director Liu,Ming-Chung |

|---|---|---|

| Office Tel. | 886-4-25825491 | 886-4-25825402 |

| E-mail: | jrchen@tss.gov.tw | tzong@tss.gov.tw |